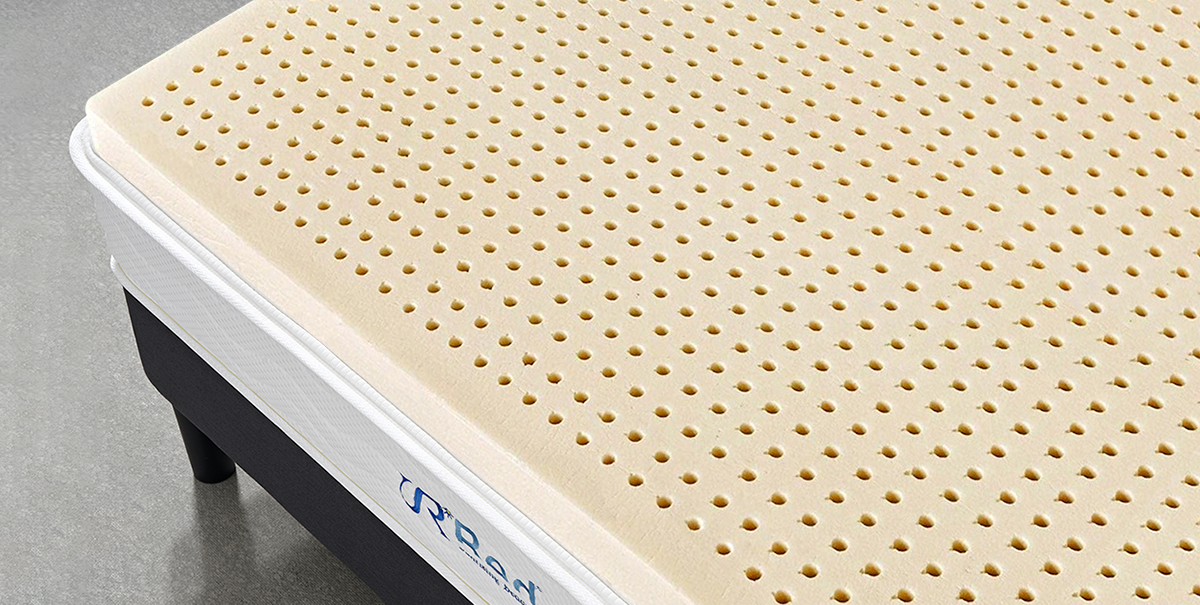

HOW TALALAY LATEX MADE

Rubber sap is whipped in a centrifuge to a froth.

Liquid latex is injected in to a mode based on formulation, then sealed and expanded by vacuum until it fills up the rest of the empty space.

The filled mold is flash frozen to below zero temperatures.

Frozen latex is baked into permanent solid form through a vulcanization process.

After the latex is removed from the mold, washed with water, and dried.